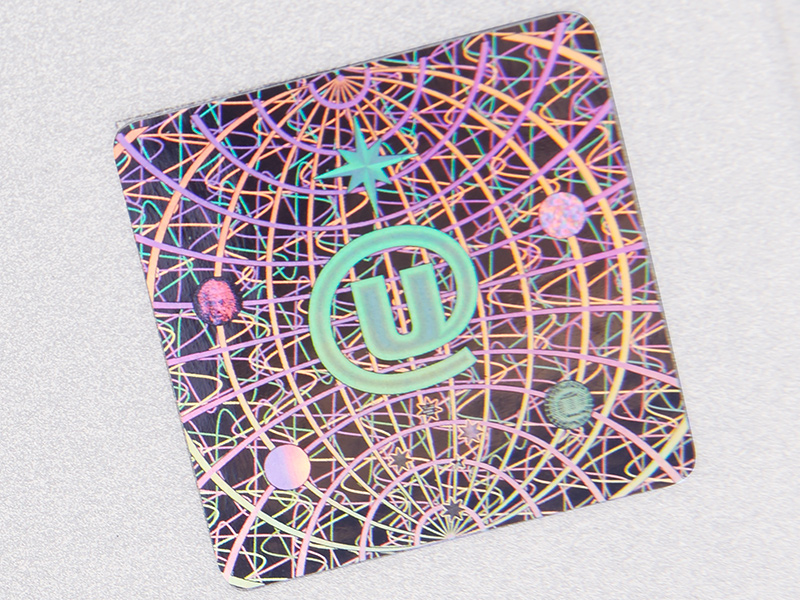

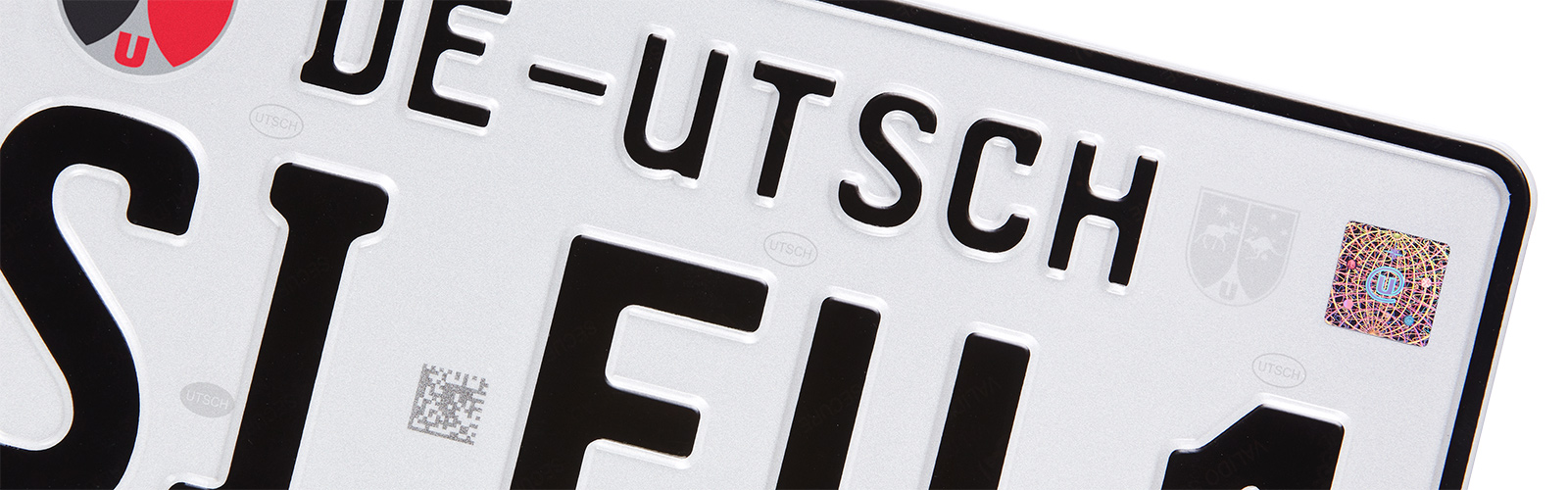

Typical elements include coats of arms, holograms, holographic hot stamping foil, laser engraving, coding and UV marking. Attempts to imitate or forge these features would be so complex (if even possible) that the supposed benefit would be outweighed by the technical complexity and cost involved.

By using the security features below, UTSCH guarantees that license plates offer the same consistent level of security as other official documents such as identity cards, passports and banknotes:

Laser treatment

A suitable means for increasing the tamper-proof security of license plates are markings that are introduced under the coating with a laser beam. These can be applied in such a way that they are only visible at a certain angle, making any attempt to counterfeit a license plate more difficult.

Individualizing markings (Bar- and 2D codes)

Already in the production process of the license plate blanks, features are introduced which clearly identify each plate. Through this, complete traceability is ensured, from the production of the blanks to the registration of the vehicle.

License plates can be provided with different codes, depending on the customer requirements.

2D-Code

Serial number

Reverse barcode

Optimised, qualified, certified and reliable

As a provider of official documents, UTSCH is subject to a regular inspection by German authorities. In addition, in its services and the processing of material, UTSCH employs the high standards set by ISO certification.

In all manufacturing steps, only materials from selected and well-known suppliers with the highest quality standards are used. The vehicle license plates manufactured on systems developed and constructed in house undergo thorough quality assurance to make sure that only tested and reliable products find their way to the customer.

An innovative pioneer in technology

From the introduction of retro-reflective film on license plates (for better visibility in the dark) to anti-fraud FE type (to prevent manipulation) and the environmentally friendly solvent-free hot stamping technique for inking the registration number, UTSCH has continually pioneered new technologies for the rest of the industry.

And we are continuing to put our stamp on development, for example with innovative security technology for vehicle license plates and tailor-made, modular systems and individual solutions.

English

English

Deutsch

Deutsch

Español

Español

Français

Français

.jpg)

.jpg)